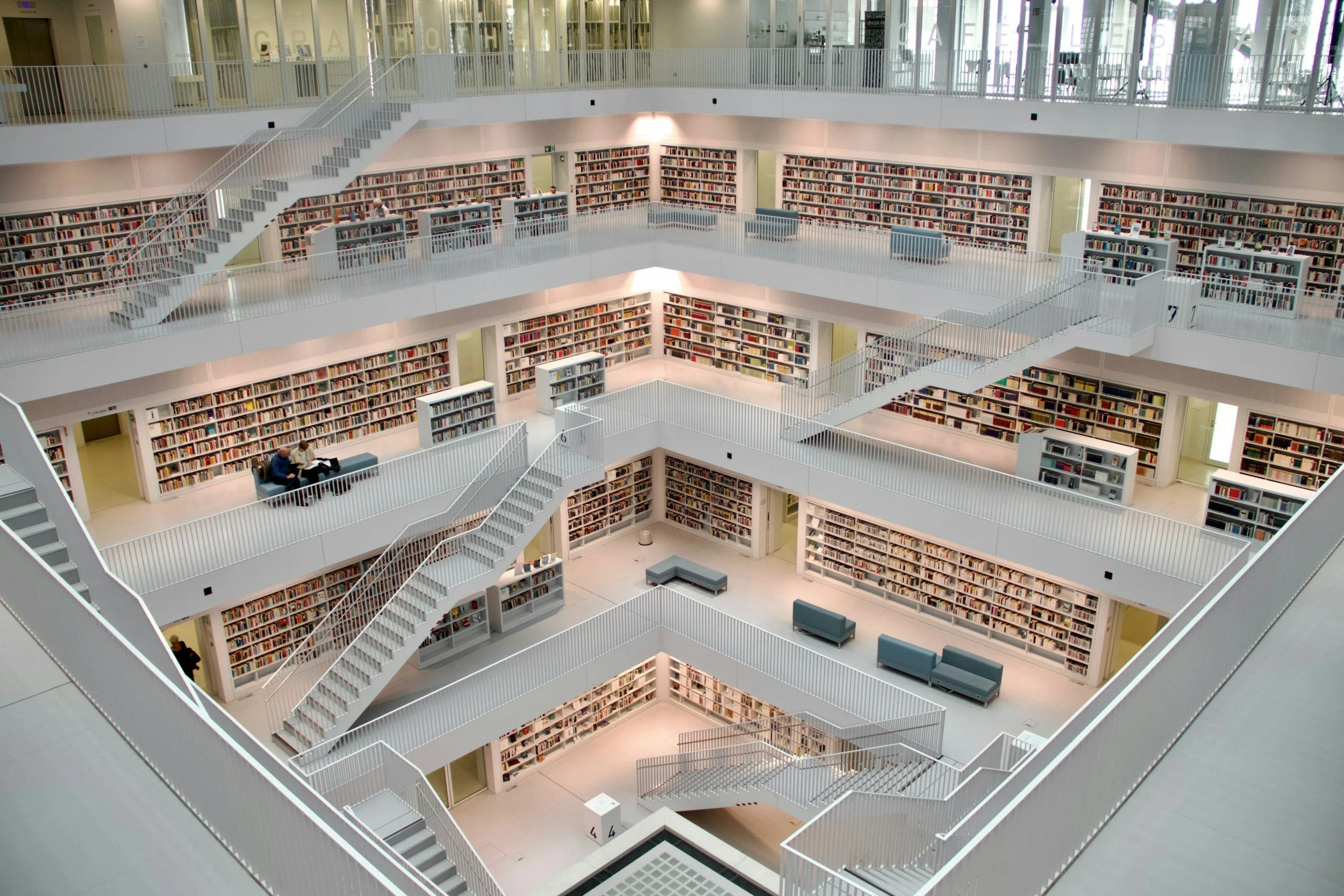

Knowledge Systems & Standards Development

How I built a centralized Knowledge System that unified our design standards, workflows, and technical resources into one accessible source of truth. This streamlined onboarding, improved consistency, and gave the team a scalable framework for collaboration and growth.

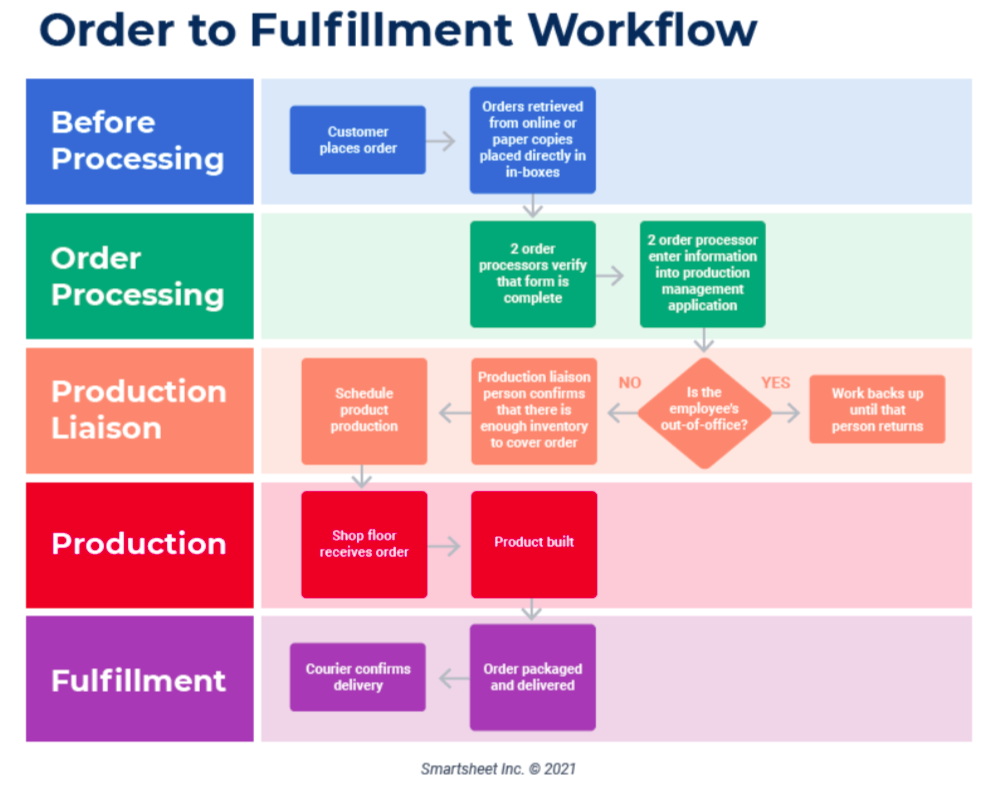

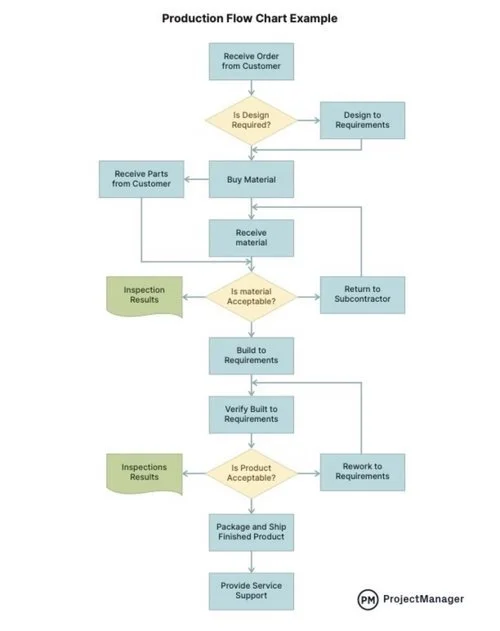

Workflow Mapping & Operational Clarity

Mapping the full workflow revealed a hard truth: our “8-hour” design process required 16 hours of real work. That insight exposed hidden tasks, clarified bottlenecks, and gave leadership the operational visibility needed to make meaningful changes.

Image by Smartsheet.com

KPI Dev. & Capacity Tracking

A unified KPI system revealed true cycle times, risks, and capacity, enabling leadership to shift from reactive decisions to proactive planning.

Building a Cross-Functional Project Management System for Operational Control

I built Smartsheet into a single source of truth for cross-functional project execution. This system aligned administration, design, production, and installation workflows while giving leadership real-time insight into capacity, risk, and execution health.

Advanced Mechanical Design & Rapid Prototyping (SolidWorks)

With over 10 years of experience in SolidWorks, I’ve designed and delivered fabrication-ready mechanical systems focused on rapid prototyping, steel weldments, and standardized model libraries. My work includes conveyor and food-handling systems, multi-story mezzanines, and modular components, often integrating new equipment into active production lines through on-site evaluation and close collaboration with fabrication and machining vendors.It All Begins Here

Smartsheet: Turning Quoting-to-Install Data Into a Strategic Asset

It All BegiI built a Smartsheet-based project management platform that captured data from quoting through installation, transforming everyday project inputs into a powerful forecasting tool. By structuring data correctly and automating its derivation, the system revealed critical misalignments between assumed budgets, stated productivity goals, and real-world performance—enabling leadership to plan with clarity instead of intuition.ns Here

Change Management — Hourly Time Tracking System

From Manual Time Logs to Operational Clarity

I designed and implemented a standardized, dashboard-driven time tracking system that transformed how leadership understood designer workload. Previously, time reporting was manual, inconsistent, and limited to total hours worked—offering no visibility into task types, job categories, or internal overhead. The new system captured time at the task level (wall vs. truss design, quotes vs. production, internal work) while remaining simple for designers to use. Within one week, the entire team adopted the tool, eliminating manual reporting and unlocking clear insights into capacity, bottlenecks, and process inefficiencies—enabling data-driven conversations between designers and leadership for the first time.It All Begins Here

Product Management Case Study

Led early-stage product ownership for a mixed reality support platform designed to enhance customer operation and service of industrial food-processing X-ray machines. Owned the product charter, rollout planning, and cross-functional execution, coordinating technicians, software development, and hardware reviews to translate real-world service needs into a hands-free digital experience. Built and managed the full delivery framework in Smartsheet, facilitated weekly stakeholder reviews, and served as the primary bridge between end users and engineering. While the product did not reach full market launch during my tenure, the project provided deep hands-on experience in hardware/software product discovery, requirements definition, and delivery under ambiguity.It All Begins Here